Basic Info.

Model NO.

TCB100

Product name

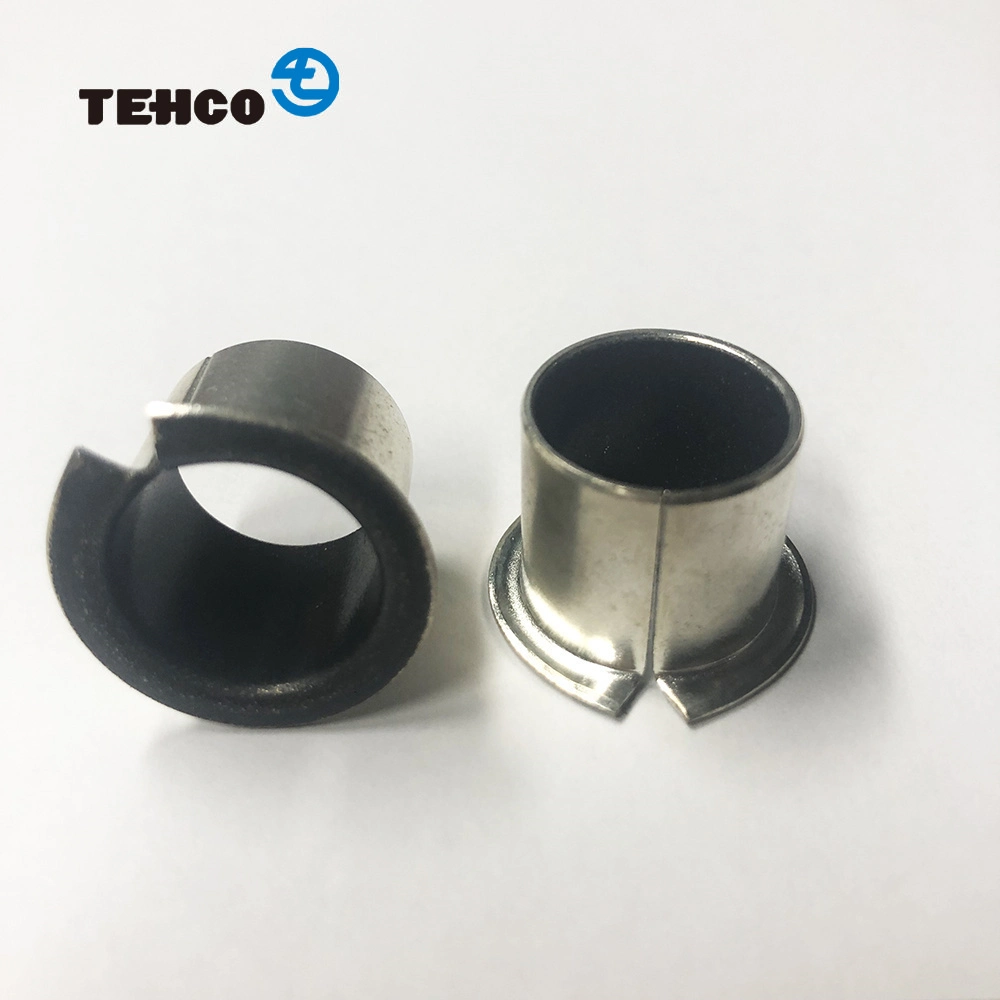

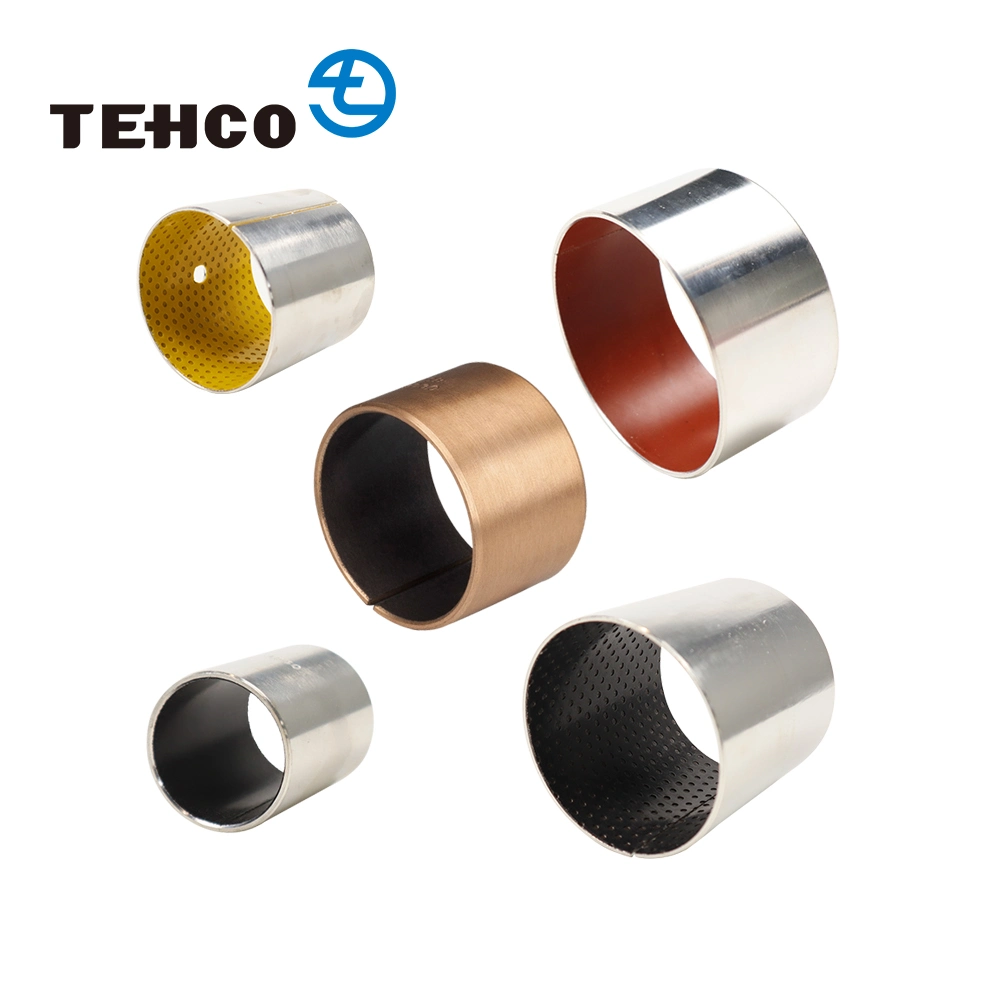

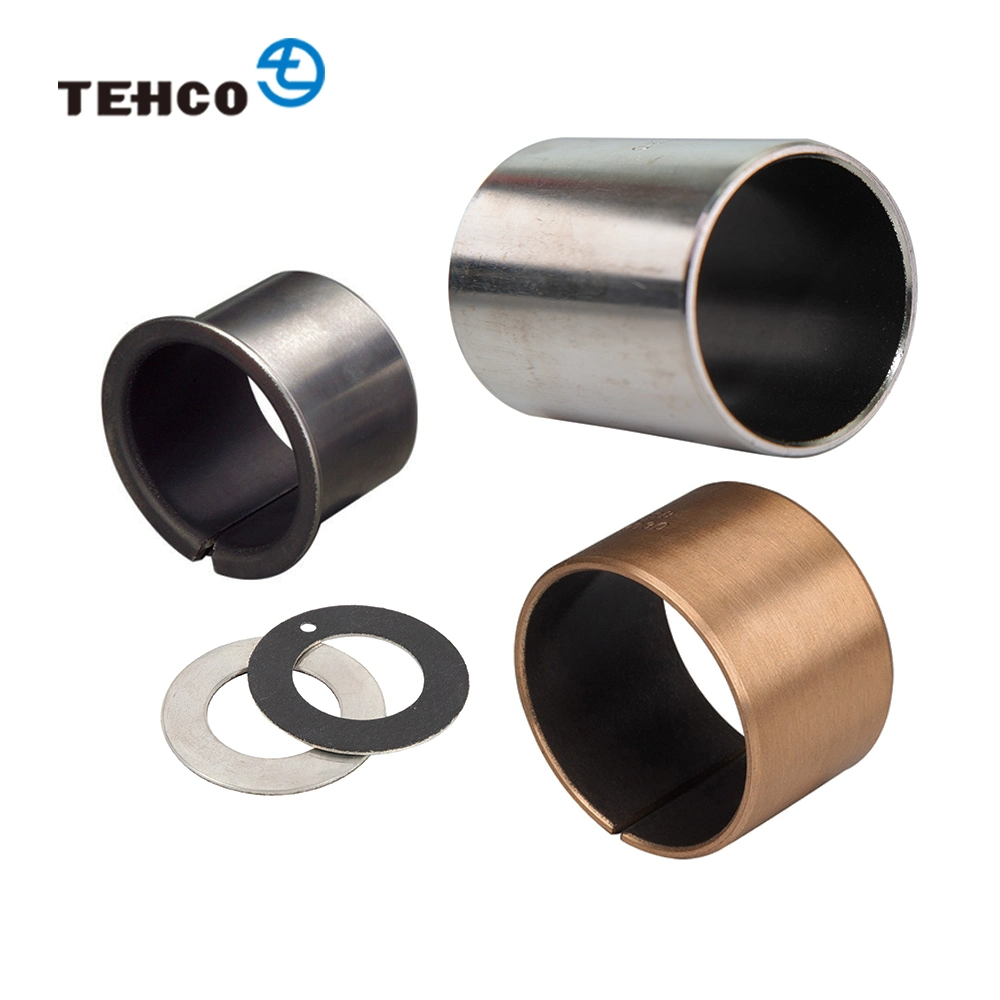

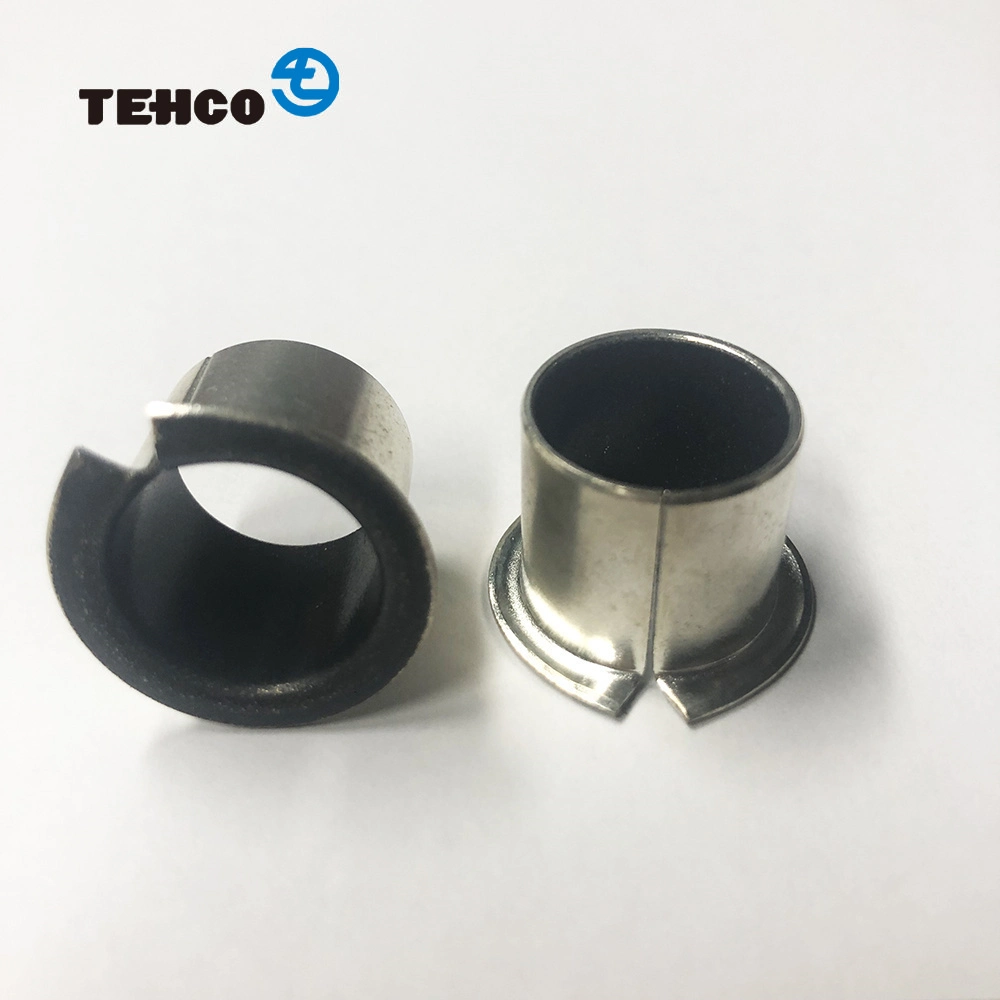

DU bushings

Sizes

Customized sizes

Processing method

Cold-extrusion

Outside surface plating

Cooper plating, tin plating, zinc plating

Structure

Split wrapped

Features

Self lubricating, maintenance free, oilless

Standard

ISO3547/DIN1494

Samples

Free samples

MOQ

100PCS

Applicable Industries

Printing, woven, totacco and gymnastic machinery

Transport Package

Anti-Rust Paper, Carton, Wood Case or Pallet

Specification

Customized

Trademark

TEHCO

Origin

China

HS Code

8483300090

Production Capacity

100000.0 Piece/Pieces Per Month

Product Description

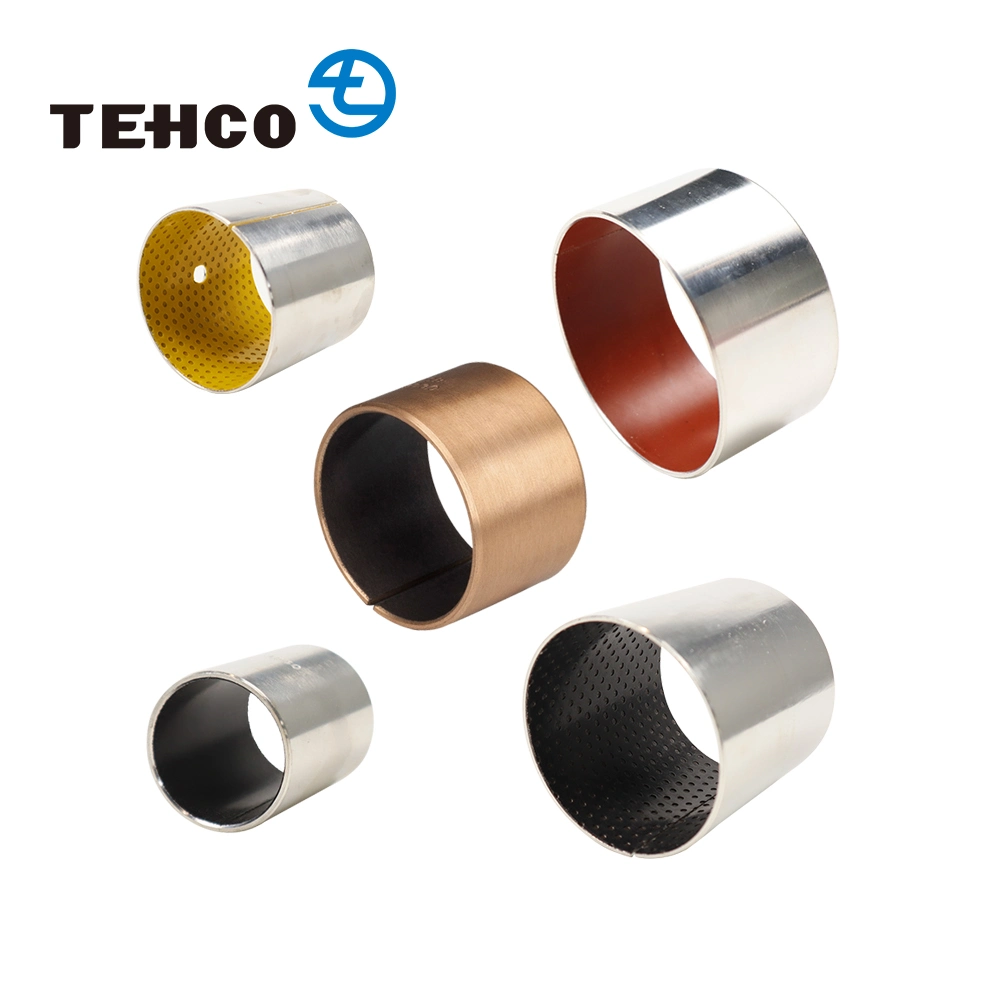

China Wholesale Steel Base Composite Metal Bush Wrapped Sleeve DU Bearing Self-lubricating Sleeve Bushing for Print Machine.

China Wholesale Steel Base Composite Metal Bush Wrapped Sleeve DU Bearing Self-lubricating Sleeve Bushing for Print Machine. PRODUCT DESCRIPTION

China Wholesale Steel Base Composite Metal Bush Wrapped Sleeve DU Bearing Self-lubricating Sleeve Bushing for Print Machine.

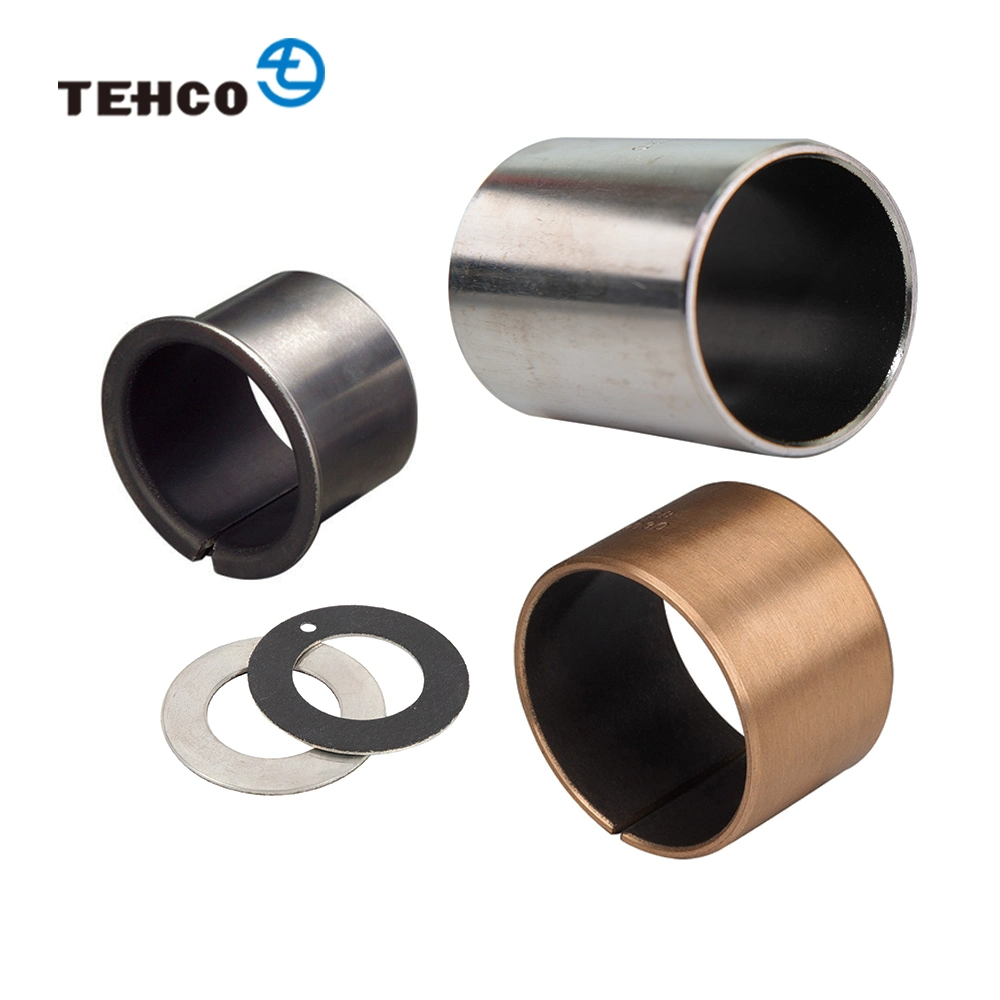

Its material structure is Steel base + Bronze powder + PTFE and filler.

It can offer the good properties of self-lubricating, anti-abrasion, low-friction, fully developing the advantages of metal and multi-element polymer.

It's applied to the printing, woven, tobacco and gymnastic machinery, etc.

China Wholesale Steel Base Composite Metal Bush Wrapped Sleeve DU Bearing Self-lubricating Sleeve Bushing for Print Machine.

Its material structure is Steel base + Bronze powder + PTFE and filler.

It can offer the good properties of self-lubricating, anti-abrasion, low-friction, fully developing the advantages of metal and multi-element polymer.

It's applied to the printing, woven, tobacco and gymnastic machinery, etc.

| Performance Index | Data | |

| Product Name | China Wholesale Steel Base Composite Metal Bush Wrapped Sleeve DU Bearing Self-lubricating Sleeve Bushing for Print Machine. | |

| Load capacity P (Dry friction) | Static Load | 250N/mm² |

| Dynamic Load | 140N/mm² | |

| Oscoillation Load | 60N/mm² | |

| Max line speed V | Dry Lubrication | 2.5m/s |

| Oil Lubrication | >5m/s | |

| PV value limit | Grease Lubrication | 1.8N/mm²· m/s |

| Oil Lubrication | 3.6N/mm²· m/s | |

| Friction coef u | Dry Lubrication | 0.08~0.20 |

| Oil Lubrication | 0.02~0.12 | |

| Mating Axis | Hardness | >220 HB |

| Roughness | Ra=0.4~1.25 | |

| Material | Steel+Bronze+(PTFE+Filler) | |

| Typical application | The printing, woven, tobacco and gymnastic machinery, etc. | |

| Working Temperature | -200~+280ºC | |

| Thermal conductivity | 40W/(m·K) | |

| Coefficient of linear expansion | 11×10-6/K | |

| Outside surface Plating | copper/tin | |

| Notice: We can also develop according to customers special request while out of this table | ||

DETAILED IMAGES

COMPANY PROFILE

EXHIBITION SHOW

PACKING AND DELIVERY

1. Inner Packing

For small products: 100PCS-200PCS per sealed plastic bag.

For bigger products: 2PCS-10PCS per plastic film roller (depends on the product size)

For bigger products: 2PCS-10PCS per plastic film roller (depends on the product size)

2. Outer Packing&Shipment Packing

8PCS-300PCS per carton (depends on the product size)

3. Shipment Packing

18-24 cartons per wood case or pallet, shockproof and safe for transportation.

FAQ

FAQ

Q: Are you trading company or manufacturer?

A: Our management is focused on exporting activities for more than ten years and we have our own bushing factory.

TEHCO is always professional and reliable. Our advantages are multiple resource integration, strong quality assurance and excellent service level. We are always responsible for our products.

Q: Hong long is your delivery time?

A: Generally 10-25 days after order. It depends on the quantity.

Q: Do you produce samples? Is it free or extra?

A: For standard products, we produce samples free of charge for our customers. And the express costs will be burdened by the customer, but can be returned after the order is placed.

Q: How to ensure the quality?

A: We produce as per the confirmed technology or drawings for each order for our customers. And our factory has a strict quality control system. We inspect goods during production according to a certain frequency and we also perform the final inspection before the goods are packed.

Q: Do you like to serve the customers only with small orders?

A: We are always glad to grow up together with all our customers whatever big or small.We hope our customers become stronger and stronger to be with us.

A: Our management is focused on exporting activities for more than ten years and we have our own bushing factory.

TEHCO is always professional and reliable. Our advantages are multiple resource integration, strong quality assurance and excellent service level. We are always responsible for our products.

Q: Hong long is your delivery time?

A: Generally 10-25 days after order. It depends on the quantity.

Q: Do you produce samples? Is it free or extra?

A: For standard products, we produce samples free of charge for our customers. And the express costs will be burdened by the customer, but can be returned after the order is placed.

Q: How to ensure the quality?

A: We produce as per the confirmed technology or drawings for each order for our customers. And our factory has a strict quality control system. We inspect goods during production according to a certain frequency and we also perform the final inspection before the goods are packed.

Q: Do you like to serve the customers only with small orders?

A: We are always glad to grow up together with all our customers whatever big or small.We hope our customers become stronger and stronger to be with us.