Basic Info.

Model NO.

Bronze Investment Casting

Pressure Chamber Structure

Vertical

Tolerance Grade

4

Casting Surface Quality Level

1

Certification

CE, RoHS, ISO 9001:2000, ISO 9001:2008, ISO9001:2015

Process Type

Die Casting

Surface Finish

Electroplating

Certificate

ISO 9001, SGS

Die Casting Machine

Die Casting

Inspection

Advanced Equipments + Professional

Dimisions

Accept OEM and ODM

Keywords 1

Bronze Casting

Keywords 2

Bronze Cast Handles

Transport Package

Wooden Crate/Carton Box

Specification

ISO IGS STEPS

Trademark

Mingyi

Origin

China

HS Code

8401200000

Production Capacity

100000PCS/Month

Product Description

OEM Fabrication Service Aluminum Bronze Investment Copper Casting

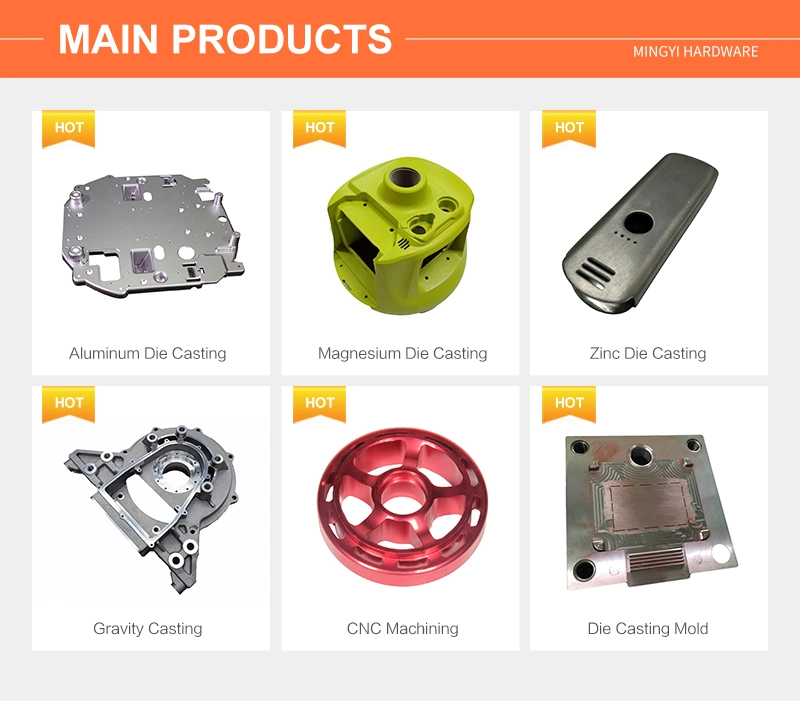

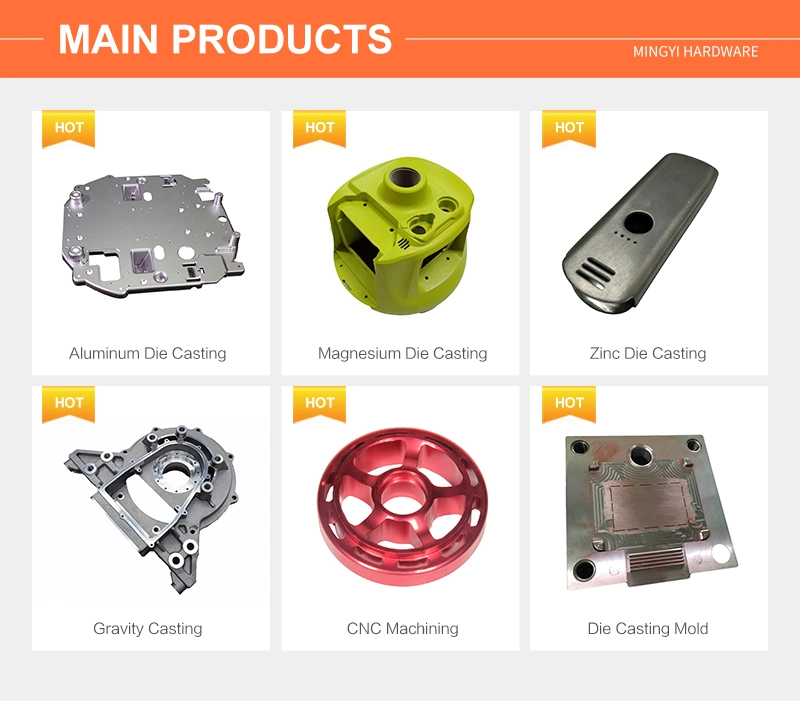

Dongguan Mingyi Hardware Products Co., Ltd. is a factory that professionally design and produce magnesium, aluminum, zinc alloy die casting, sand casting, gravity casting, stamping, aluminum profiles, and CNC machining. It provides all-round production services from the design and development of mould to the forming and post-processing of casting products and surface treatment.

The products are mainly used on 3C industry, lighting decoration, electrical appliances, auto parts, furniture parts, electric tool, medical equipment, intelligent automation equipment and so on. It is exported to Europe,America and Southeast Asia

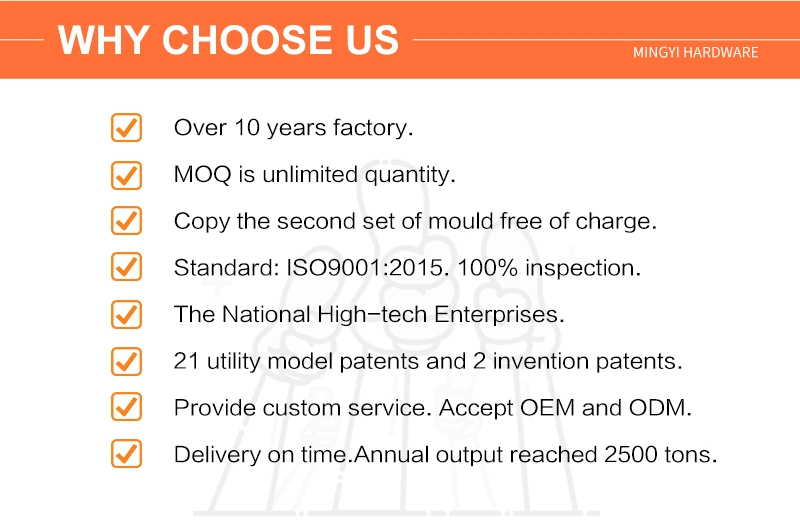

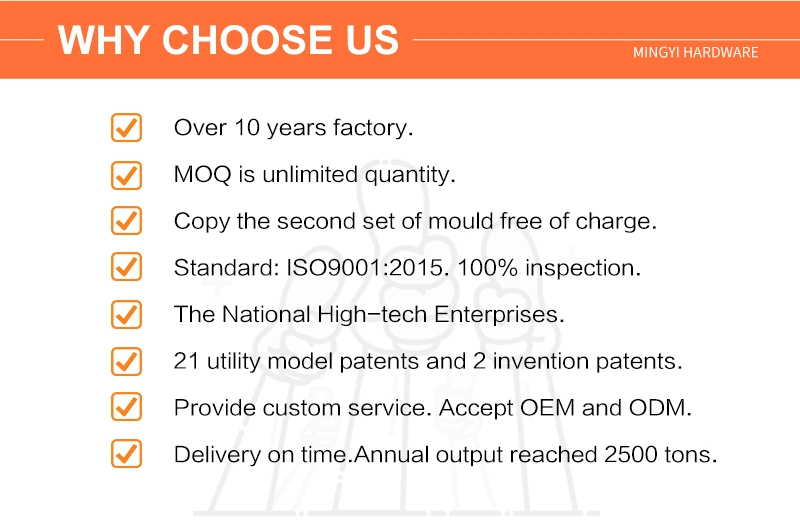

The company was founded in 2010, has 10 years' experience about development and manufacture management, It has more than two dozen patented technologies (including two invention patents) and was recognized as a national high-tech enterprise in December 2017, We have obtained ISO9001:2015 Certificate in May 7th 2012.

Our company's production workshop consists of mould department, casting department, processing department, CNC department, paint department, etc. It has 12 professional die design engineers, senior mould making technicians, die-casting engineers, and CNC programmers. The quantity of production workers can be reach to two hundred.

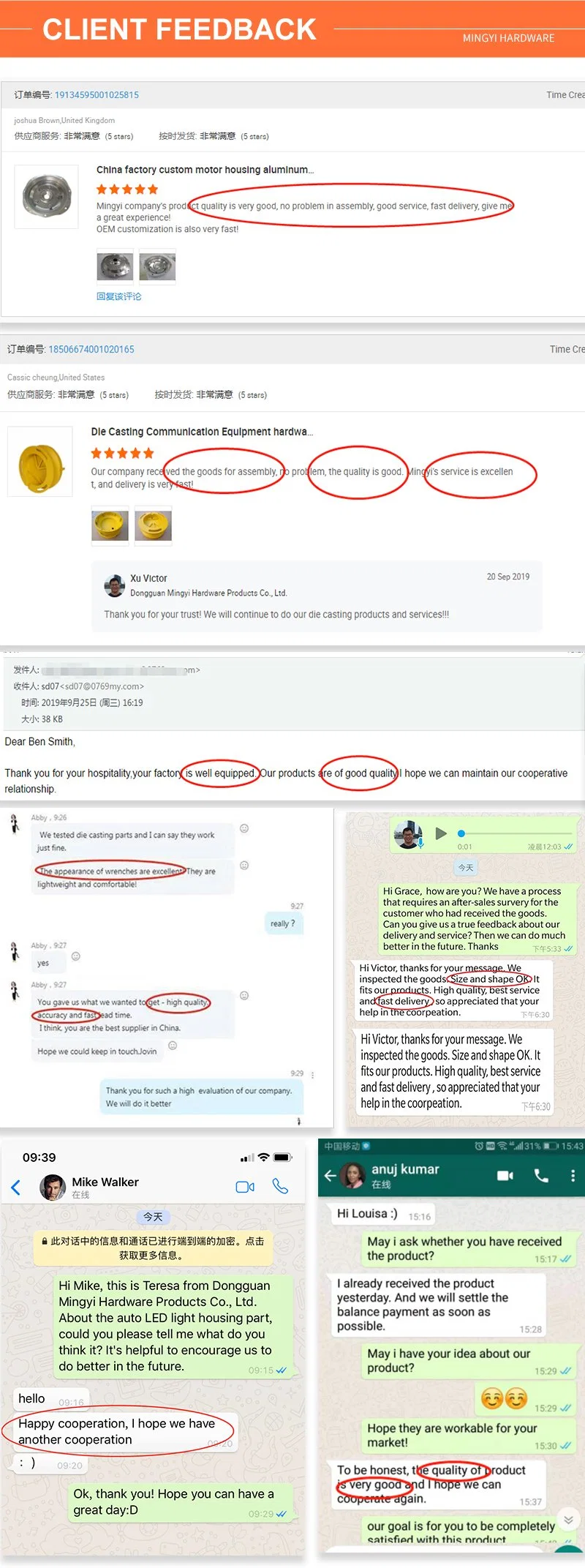

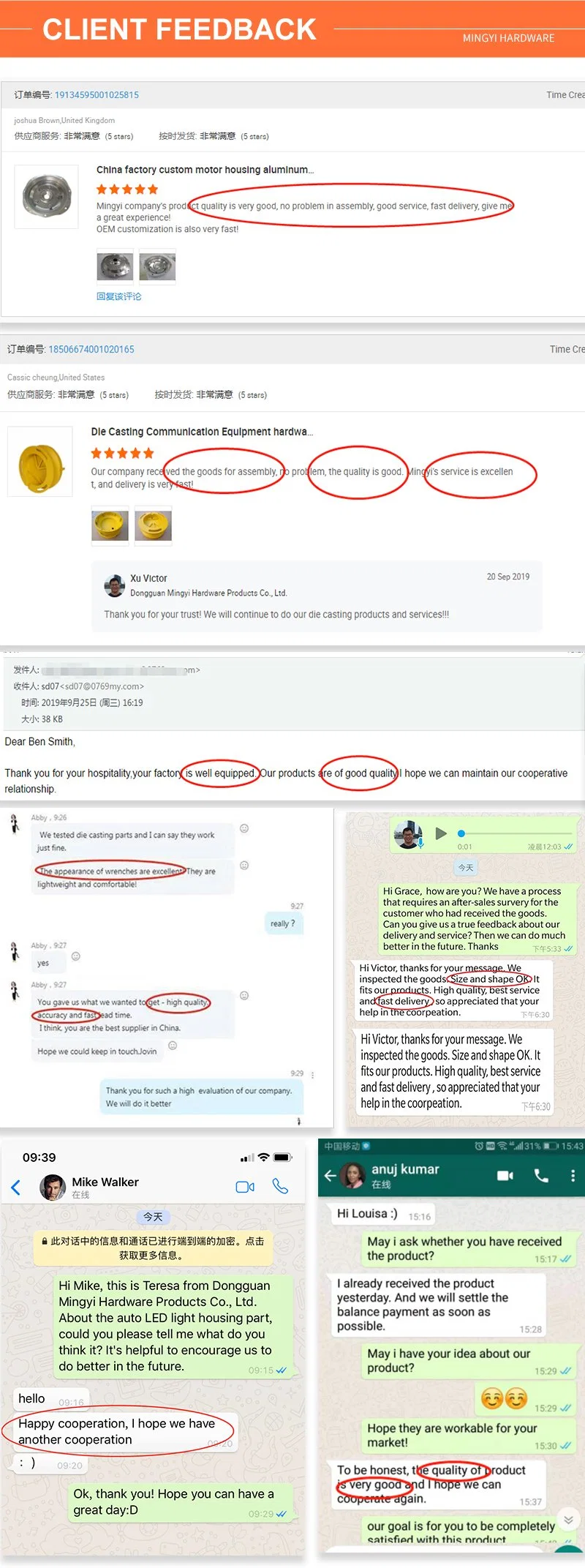

Not the best, only better! We hope we'll be the one of the hardware casting specialist. Welcome to pay a visit to our company.

Official website: https://www.diecastingtech.com/

| Material | Aluminum alloy: ADC12, ADC10, A360, A380, A356, 6061, 6063 Magnesium alloy: AZ91D, AM60B, Zinc alloy: ZA3#,ZA5#,ZA8# |

| Processing Craft | Drawings→ mould making → die casting →rough machining → CNC machining→surface treatment →product checking→ packing →delivery |

| Tolerance | ± 0.05mm |

| Surface Treatment | Electroplating, Chrome Plating, Zinc Plating, Nickel plating, Electrophoresis, Anodization, Polishing, Sandblasting, Passivation, Powder coating, Spray painting, Etc. |

| Quality Assurance | ISO9001:2015 Certified, SGS Certification |

| Quality Guarantee | Two years |

| Inspection | 1.Foundry in-house: 100% inspection on critical dimension; 100% on appearance. 2.Third Party inspection available upon requirement |

| Mainly Testing Facility | Three-dimensional measuring instrument (CMM), Salt spray test box, Dynamic balance detector, Pneumatic detection |

| Features & Advantage | 1.High machining accuracy, the flatness within 0.1mm. 2.High strength and not easy to deform, has good electrical and thermal conductivity. 3.High finish appearance,smooth surface roughness is Ra1.6 after machining. 4.The machining precision is high and the assembly structure is seamless. 5.No granules, no spots and no painting peel off in appearance. 6.Smooth appearance, corrosion resistance. 7.Pass 20000 Times Wear Resistance Test. |

| Standard | 1.Aluminum alloy: ISO3522-84, ASTMB85-96, JISH5302:2000, EN1706:1998 2.Magnesium alloy: ISO/DIS16220-1999, ASTMB93/B93M-98, EN1754-1997 3.Zinc alloy: ISO301-1981,ASTMB327-98, JISH2021:1999, EN12844:1998 |

| Application | 3C industry, lighting decoration, electrical appliances, auto parts, furniture parts, electric tool, medical equipment, intelligent automation equipment,other metal casting parts. |

Dongguan Mingyi Hardware Products Co., Ltd. is a factory that professionally design and produce magnesium, aluminum, zinc alloy die casting, sand casting, gravity casting, stamping, aluminum profiles, and CNC machining. It provides all-round production services from the design and development of mould to the forming and post-processing of casting products and surface treatment.

The products are mainly used on 3C industry, lighting decoration, electrical appliances, auto parts, furniture parts, electric tool, medical equipment, intelligent automation equipment and so on. It is exported to Europe,America and Southeast Asia

The company was founded in 2010, has 10 years' experience about development and manufacture management, It has more than two dozen patented technologies (including two invention patents) and was recognized as a national high-tech enterprise in December 2017, We have obtained ISO9001:2015 Certificate in May 7th 2012.

Our company's production workshop consists of mould department, casting department, processing department, CNC department, paint department, etc. It has 12 professional die design engineers, senior mould making technicians, die-casting engineers, and CNC programmers. The quantity of production workers can be reach to two hundred.

Not the best, only better! We hope we'll be the one of the hardware casting specialist. Welcome to pay a visit to our company.

Official website: https://www.diecastingtech.com/