- Overview

- Product Description

- Products List

- Certifications

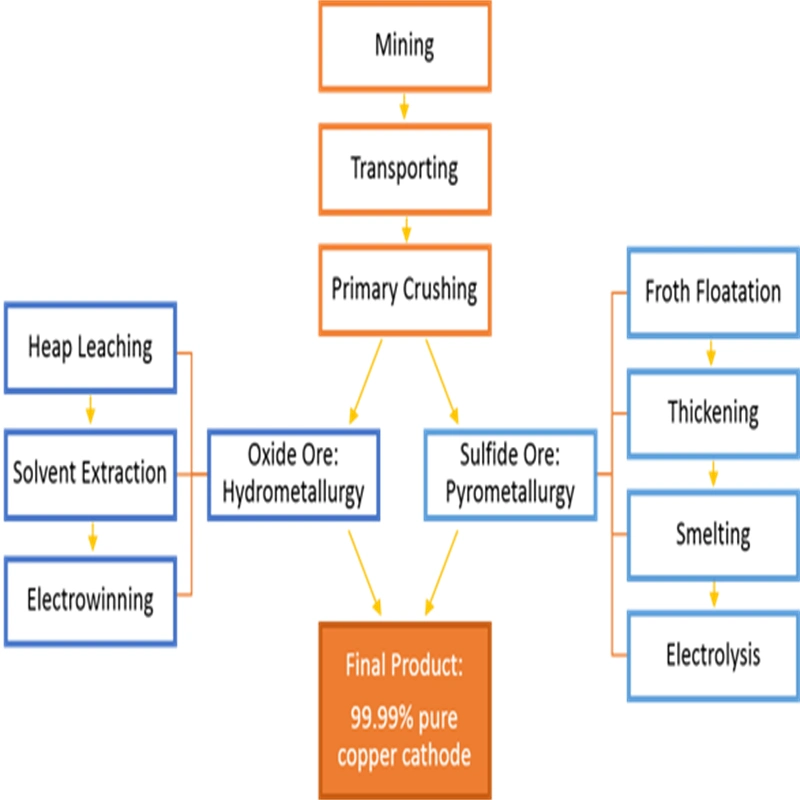

- Production flow

- Packaging & Shipping

- Company Profile

- FAQ

Basic Info.

Product Description

| Product Name | Hard 2mm Thickness Copper Shapes C71520 Bronze Profile for Architecture |

| Standard | ASTM, AISI, DIN, EN, GB, JIS, etc |

| Certification | SGS, ISO, RoHS, CCC |

| Material | C36000, C36010, C86300, C90500, C91100, C91300, C93700, C65100, C65500, C66100, C11000, C14500, C14700, C36500, C37000, C37700, C46400, C48200, C48500, C61900, C62300, C63000, C63200, C64200, C64210, C65500, C67500, C67600, C69300, C70620, C71520, C77400, C67000, C67500, C67600 |

| Shapes | Square, Flat, Round, Hollow, Oval, Triangle, Y-profiles, U-profiles, L-profiles, T-profiles, H-profiles, or as customer's requested |

| MOQ | 300Kg |

| Package | Standard export package, suited for all kinds of transport, or as required. |

| price term | EXW, FOB, CFR, CIF, DDP, etc. |

| Contact | If you have any questions, please feel free to contact me. We are sure your inquiry or requirements will get prompt attention. |

| GRADE | TECHNOLOGY | TEMPER |

| COPPER | HOT ROLLED | M20 |

| COLD ROLLED | O60,H01,H02,H04,H06,H08 | |

ASTM B124/B124M-2020

Standard Specification for Copper and Copper Alloy Forging Rod, Bar, and Shapes

This specification establishes the requirements for copper (UNS Nos. C11000, C14500, and C14700) and copper alloy (UNS Nos. C36500, C37000, C37700, C46400, C48200, C48500, C61900, C62300, C63000, C63200, C64200, C64210, C65500, C67500, C67600, C69300, C70620, C71520, and C77400) forging rods, bars, and shapes. The material for manufacture shall be a cast rod, bar, or billet of such purity and soundness as to be suitable for processing by hot working, cold working, and annealing to produce a uniform wrought structure in the finished product. Products shall be produced in tempers H50 (extruded and drawn), M20 (as hot rolled), and M30 (as hot extruded). Products shall be tested and shall adhere to dimensional (diameter, thickness, width, length, shape, and straightness), mechanical, and chemical composition requirements.

MATERIALS

C67500: With a chemical composition of 70% Cu, 29% Zn, and 1% Pb, C67500 is a high-strength copper alloy. It exhibits excellent corrosion resistance in marine environments and offers good machinability. This material is often used for applications requiring high-stress corrosion resistance, such as fittings, valves, and marine hardware.

C67600: Copper alloy C67600, also known as naval brass, comprises 60% Cu, 39% Zn, and 1% Sn. Apart from good corrosion resistance in seawater, C67600 offers high strength and excellent hot workability. It finds applications where resistance to corrosion and biofouling is essential, such as marine hardware, condenser tubes, and heat exchangers.

C69300: C69300, a high-strength copper alloy with 88% Cu, 8% Ni, and 4% Sn, is known for its exceptional resistance to stress-corrosion cracking. It exhibits excellent mechanical properties, including high strength, wear resistance, and machinability. C69300 is commonly used in seawater applications, such as pump components, valve stems, and fasteners.

C70620: By comprising 90% Cu, 10% Ni, and small amounts of Fe and Mn, C70620 offers excellent corrosion resistance, particularly in saline environments. This alloy shows high strength, good formability, and great weldability. It finds applications in seawater piping systems, heat exchangers, and oil refinery equipment due to its superior resistance to pitting, crevice corrosion, and stress-corrosion cracking.

C71520: C71520, or copper-nickel alloy, is composed of 70% Cu and 30% Ni. This alloy possesses remarkable resistance to marine corrosion, biofouling, and erosion. With good strength, ductility, and weldability, C71520 is widely used in heat exchangers, condensers, desalination plants, and various seawater-related applications.

C77400: This copper alloy consists of approximately 1% Ni and 0.8% Sn. It offers good corrosion resistance, excellent machinability, and high strength. C77400 is often used in marine environments, such as propeller and pump components, as well as for fittings, valves, and other hardware.

C67000: Comprised of 63% Cu, 35% Zn, and 2% Pb, C67000 is a high-strength brass alloy. It exhibits good corrosion resistance, machinability, and ductility. C67000 is commonly employed in applications requiring high mechanical strength and good electrical conductivity, such as electrical connectors, fasteners, and switch parts.

Copper Profiles

Copper profiles are commonly used in distribution panels and switchboards delivering key electrical advantages. Profiles are more expensive and difficult to manufacture than flat bars due to the technical requirements such as they provide a more fragile production process, more complicated packaging, and a complex design. Although the profile offers a more detailed process, its unique design enables the manufacturer to meet the demands of individual projects.

Typically, Copper profiles are used in power and electrical engineering, onshore and offshore wind power, mechanical engineering, and supply equipment. Copper profiles are an effective way to reduce the weight of Copper conductors in an existing product. Profiles also allow for flexible designing and can meet the requirements for exact designs in individual jobs. Profiles can be designed to allow fast, hole-free assembly and jointing, which can significantly reduce the time required to assemble bars in a cabinet, improving consistency and quality. Due to the increased surface area of the Copper, the profile can assist in the heat dispersion as the larger shapes and sizes increase the conductivity.

| Type | (GB) | (ISO) | (ASTM) | (EN) | (JIS) | (BS) | (DIN) |

| Red copper | TU2 | Cu-OF | C10100 | CW008A | C1011 | C101 | OF-Cu |

| T2 | Cu-FRHC | C11000 | C1100 | C101 | E-Cu58 | ||

| TP2 | Cu-DHP | C12200 | CW024A | C1220 | C106 | SF-Cu | |

| TP1 | Cu-DLP | C12000 | CW023A | C1201 | SW-Cu | ||

| Sliver copper | TAg0.1 | CuAg0.1 | C10400 | C1040 | CuAg0.1 | ||

| Brass | H90 | CuZn10 | C22000 | CW501L | C2200 | CZ101 | CuZn10 |

| H70 | CuZn30 | C26000 | CW505L | C2600 | CZ106 | CuZn30 | |

| H68 | C26200 | CW506L | C2620 | CuZn33 | |||

| H65 | CuZn35 | C27000 | CW507L | C2700 | CZ107 | CuZn36 | |

| H63 | CuZn37 | C27200 | CW508L | C2720 | CZ108 | CuZn37 | |

| H62 | CuZn40 | C28000 | CW509L | C2800 | CZ109 | ||

| Tin-Bronze copper | QSn4-0.3 | CuSn4 | C51100 | CW450K | C5111 | PB101 | CuSn4 |

| CuSn5 | C51000 | CW451K | C5101 | CuSn5 | |||

| QSn6.5-0.1 | CuSn6 | C51900 | CW452K | C5191 | PB103 | CuSn6 | |

| QSn8-0.3 | CuSn8 | C52100 | CW453K | C5210 | CuSn8 | ||

| QSn6.5-0.4 | |||||||

| Zn-white copper | BZn18-18 | CuNi18Zn20 | C75200 | CW409J | C7521 | NS106 | CuNi18Zn20 |

| BZn18-26 | CuNi18Zn27 | C77000 | CW410J | C7701 | NS107 | CuNi18Zn27 | |

| BZn15-20 | C7541 |

Typical Uses

General Characteristics | Applications |

| Good Electrical and Thermal Conductivity Good Electroplating Ability Good Corrosion Resistance Good Cold Forming and Deep Drawing Qualities Perfect Soldering and Welding Excellent Against Stress Corrosion Cracking | Electric and Electronic Industry Automotive Industry Construction Industry Circuit Breakers Contact Springs Lead Frames Roofing Jewelry E.V. Components |

Products List

Certifications

Quality is an integral part of our Business Principles. The quality policy guides us to deliver products and services that exceed the customers' expectations and meet all the standards. These principles have helped us to get recognition as a trusted vendor from customers around the world. Maxi Metal Products are trusted and chosen by customers all over the world. This trust is based upon our quality certification and our reputation for consistently delivering high-quality products.

- Blanking

- Coining

- Drawing

- Etching

- Forming and Bending

- Piercing and Punching

- Shearing

- Spinning

- Squeezing and Swaging

- Stamping

Who We Are?

Tianjin Zhongyantiancheng Steel Trading Co., Ltd

Customers Visiting

Q1:Can you send samples?

A: Of course, we can provide customers with samples and express shipping services all over the world.

Q2:What product information do I need to provide?

A: Please kindly provide the grade, width, thickness, surface treatment requirement should you have, and quantities you need to purchase.

Q3:It's my first time importing steel products, can you help me with it?

A: Sure, we have an agent to arrange the shipment, we will do it together with you.

Q4:How long does your delivery time take?

A: In general, our delivery time is within 7-15 days and may be longer if the quantity is extremely large or special circumstances occur.

Q5: How many countries have you already exported to?

A: We have exported to America, Canada, Brazil, Chile, Colombia, Russia, Ukraine, Thailand, Myanmar, Vietnam, India, Kenya, Ghana, Somalia, and other African countries. Our export experience is rich, we are familiar with different market demands, can help customers avoid a lot of trouble.

Q6:Can I go to your factory to visit?

A: Of course, we welcome customers from all over the world to visit our factory.

Q7:Does the product have a quality inspection before loading?

A: Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed and customers can appoint third parties to inspect the products before loading too.