Basic Info.

Product Description

Product Description

| Process | Sand casting, resin casting, precoated sand casting |

| Specification | 1.Material: iron, aluminum, bronze, steel 2.Standard: ASTM\DIN\BS\JIS\GB. 3.Surface finish: blasting, deburr, sharp edges 4.Weight:0.1-50kg. |

| Production facility | 1.Casting facility: medium-frequency induction furnace, box resistance furnace, heat treatment furnace, flame cutting machine, shot-blasting machine, sand-blasting machine. 2.Machining facility: CNC,NC lathe,ordinary machine tools,NC milling machine, polishing machine. |

| Heat treatment | Annealing/Tempering/Normalizing. |

| Test facility | spectrometer, tensile test machine,impact tester, hardness test machine,CMM. |

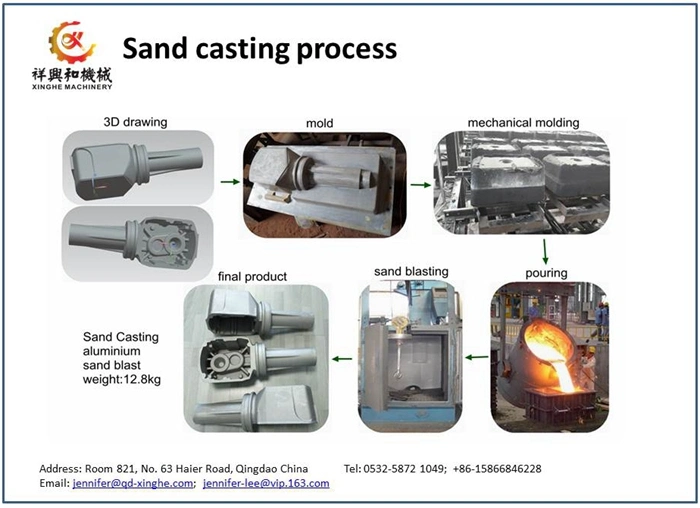

2.sand casting flow chart:

prepare drawing--check drawing--design mould--mechanical molding--melting and pouring--cooling--sand removal--grinding--sand blast as follow:

Company Information

Qingdao Xinghe Machinery Co.,Ltd.

Sand casting:

Plant has large-scale casting equipment of 50 sets, we have different technology with different type of sand kind and parts shape. The largest casting we can cast is 15 tons. Our yearly capacity for sand casting is about 2000 tons for cast steel and 30000 tons for cast iron.

Inspection process:

In order to ensure the quality of the orders, our independent QC members to carry out strict inspection

1.) wooden, carton;

2.) pallet;

3.) as customers' requirement.

FAQ- 1. How can I get thequotation?

Please send us information for quote: drawing, material, weight, quantity and request.

- 2. If we don't have drawing, can you make drawing for me?

Yes, we make the drawing of your sample and duplicate the sample.

- 3. When can I get thesample?

Sample: 25-30 days after you start to make mold. The accurate time depends on your product.

- 4. What is your main order time?

Order time: 35-40 days after the payment. The accurate time depends on your product.

- 5. What is yourpayment method?

Tooling: 100% TT advanced.

Main order: 50% deposit, balance 50% to be paid before shipment.

- 6. Which kind of file format you can read?

PDF, ISGS, DWG, STEP, MAX..

- 7. If you export to our country before, can I get the information of your import customer in our country?

We can't offer you all the information of our customer because we have duty to protect our customers' privacy. But we can provide you some part of B/L.